Perfect Fit:

At-Home 3D Scanned Back Brace

———————————— HYPOTHESIS

Measuring for new back braces is a timely proces…

Individuals with spinal deformities require a new back brace as they grow, typically requiring an in-person check up every 6-12 months. For pre-fabricated braces, these measurements are taken by hand, whereas custom braces utilize 3D scans of an individual in their measuring process.

I hypothesize that introducing at-home 3D scanning technology into the measuring process for all back braces will provide added convenience for the user, and reduce the need for in-person visits.

ROLE

Project Lead

TEAM

Katie Bush

DURATION

April, 2022

6 weeks

———————————— BACKGROUND RESEARCH

Background research was performed on the different spinal deformities and the subsequent back brace devices that are used to correct the deformity and prevent its further progression.

While exploring braces on the market, different problems with these braces became apparent.

Some problems identified with the existing back braces on the market are:

Children only wear braces for a fraction of the suggested time

Trapped heat and low breathability causes sweating and unwanted moisture

Braces are often worn under clothes to conceal the device

Braces need to be repurchased as the individual grows

Braces require custom measurements to be taken per individual

Manufacturing individually constructed braces can take time

3D Scanning Technology

Many individuals who require back braces must attend in-person office visits to get properly measured for new back braces. This process can be inconvenient and time consuming. Furthermore, young kids my need to be re-measured more frequently, as their bodies are growing at a faster rate.

Recent advancements to 3D scanning technology has allowed for scans to be taken with smartphone cameras, allowing for just about anyone to produce their own 3D scans of objects.

This leaves an opportunity to introduce at-home scans into the measuring process for back braces, offering a more convenient option than being measured in the office.

For this project, 3D scans were taken of a model with the help of an iPhone app and the rear camera. This mesh file was then refined in Fusion 360.

Traditional Process:

At Home Process:

———————————— MOOD BOARD

Patterns and textures were curated from nature and inspired by biophilia. Incorporating these organic elements not only adds aesthetic appeal, but also enhances breathability, creating a harmonious blend of style and comfort.

Key Words:

Breathable

Beautiful

Comfortable

Easy

———————————— FORM EXPLORATION

Exploration was carried out through Gravity Sketch in the VR space.

Overall form and pattern were explored and were sketched directly on top of the mesh scan.

———————————— PATTERN EXPLORATION

Exploration was carried out through Gravity Sketch in the VR space. Overall form and pattern were explored and were sketched directly on top of the mesh scan.

———————————— FINAL CONCEPT

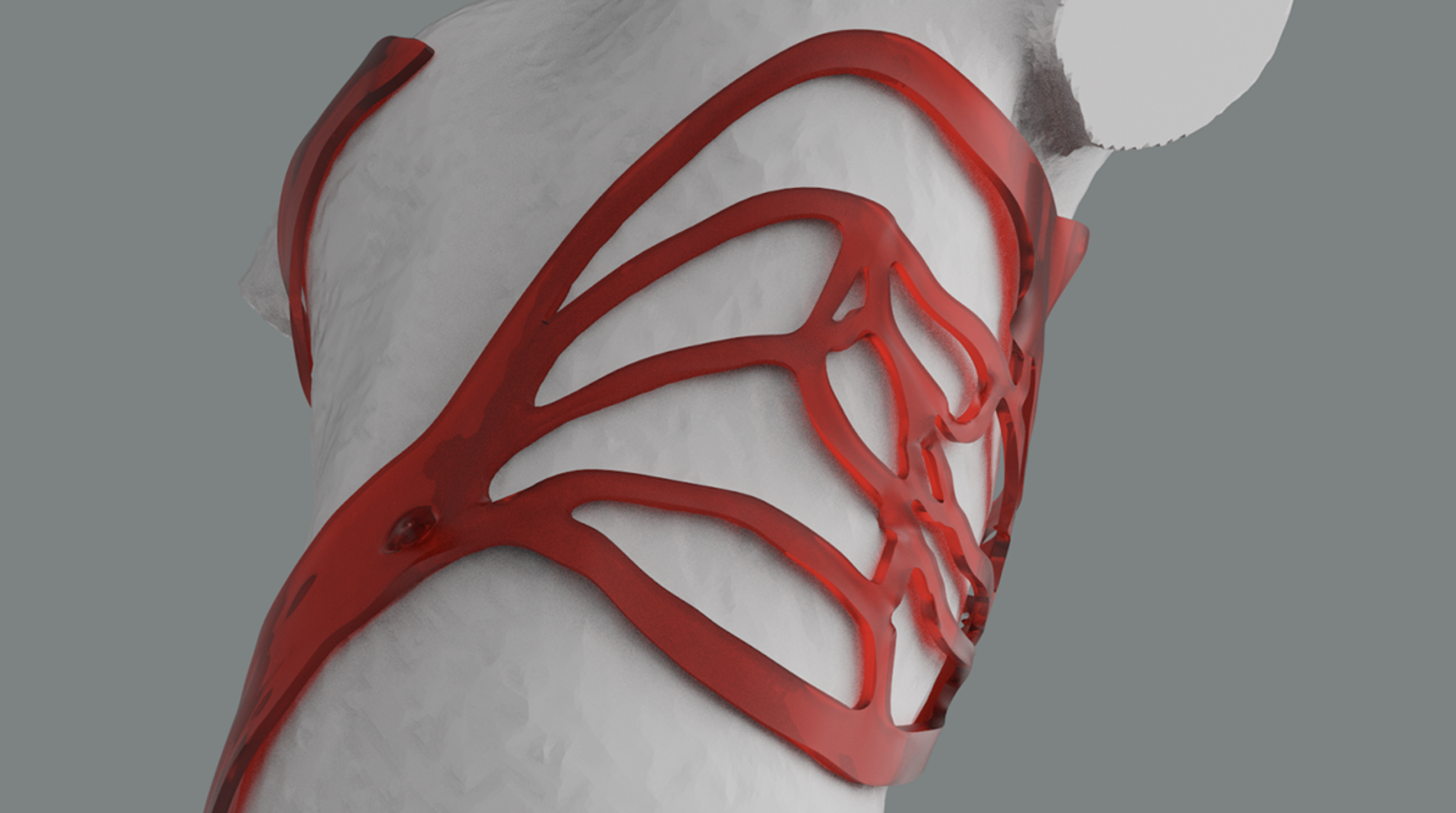

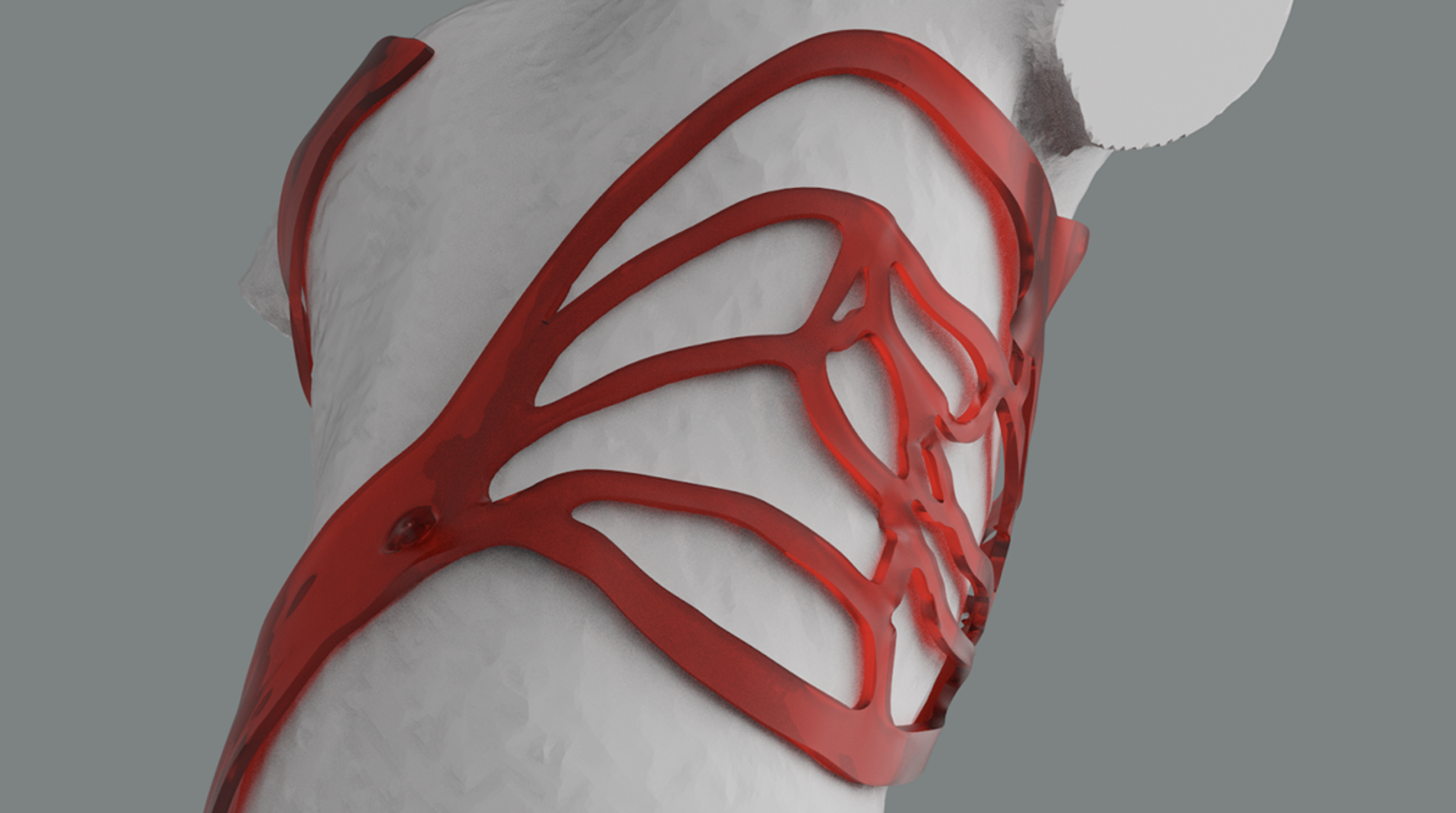

Once the form and pattern were refined and polished, CMF (Color, Material, Finish) was then applied to enhance the overall aesthetic.

These braces would be measured with 3D scanning software, modeled through CAD and produced with CAM (computer aided manufacturing).